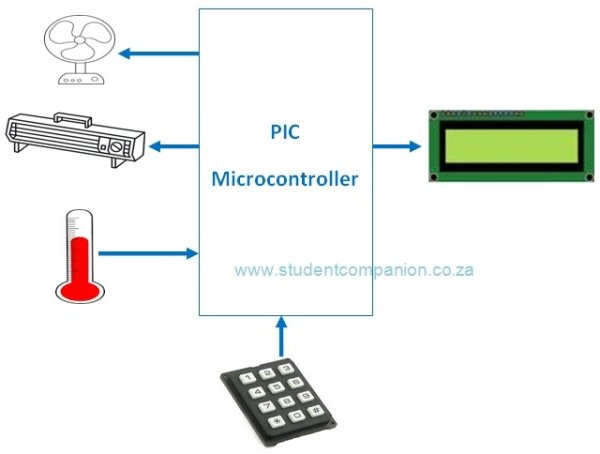

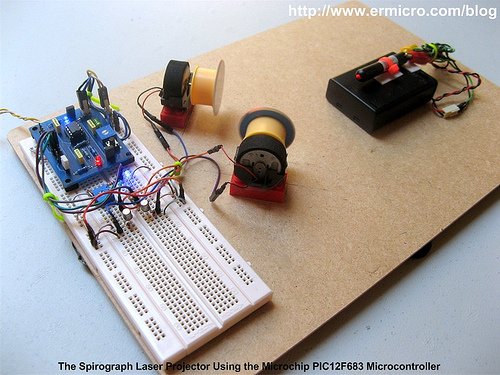

The 8 pins PIC12F683 microcontroller is one of the smallest members of the Microchip 8-bit microcontroller families but equipped with powerful peripherals such as ADC and PWM capabilities. This make this tiny microcontroller is suitable for controlling the DC motor speed. In order to demonstrate the PIC12F683 capabilities and to make this tutorial more attractive, I decided to use the PIC12F683 microcontroller to generate simple and yet fascinating laser light show from a cheap keychain laser pointer.

![Building your own Simple Laser Projector]()

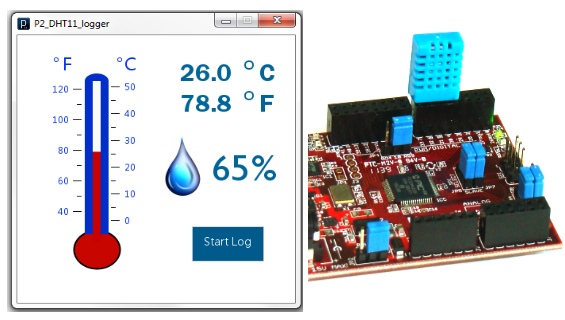

The basic of laser light shown in many entertainments club or park mostly use two method; the first one is to beam the laser shower on the spectators and the second one is to display the laser drawing pattern on the screen. On this tutorial we are going to build the laser projector that displays the spirograph pattern on the screen using the tiny Microchip PIC12F683 microcontroller.

The principle of making the spirograph laser projector is to use at least two DC motors with the attached mirror on it, these mirrors then will deflect the laser beam from one DC motor mirror to the second DC motor mirror and then finally to the screen. By controlling each of the DC motors spinning speed we could generate a fascinating laser spirograph pattern on the screen as shown on this following picture.

The best way to control the DC motor speed is to use the PWM (pulse wave modulation) signal to drive the DC Motor and because we want to change the DC motor speed manually, therefore we need to use the trimport or potentiometer to control each of the DC motors speed. Hmm, this sound like an appropriate job for the microcontroller but could we use this tiny 8 pins PIC12F683 microcontroller to handle this task?

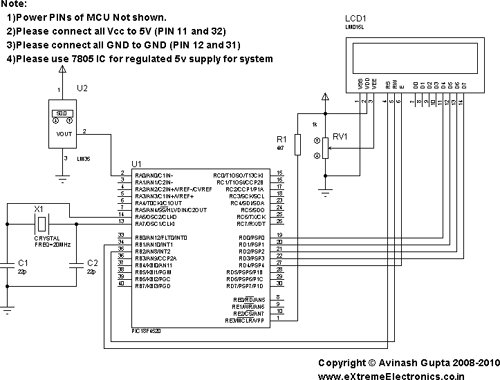

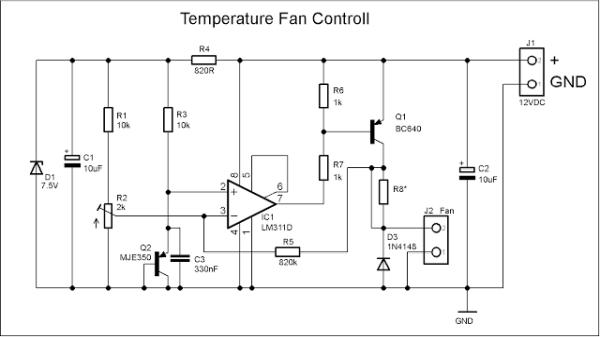

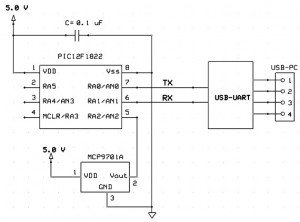

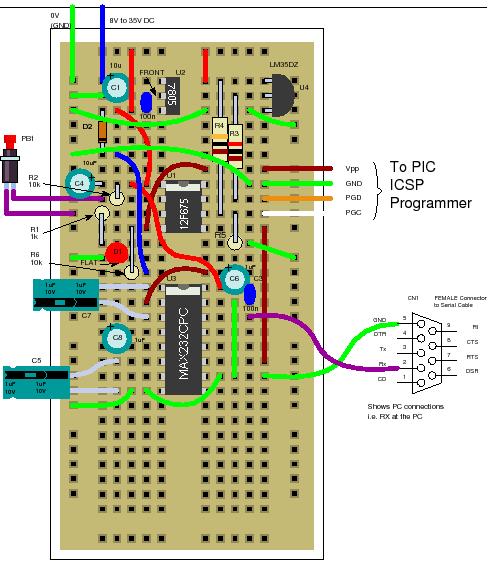

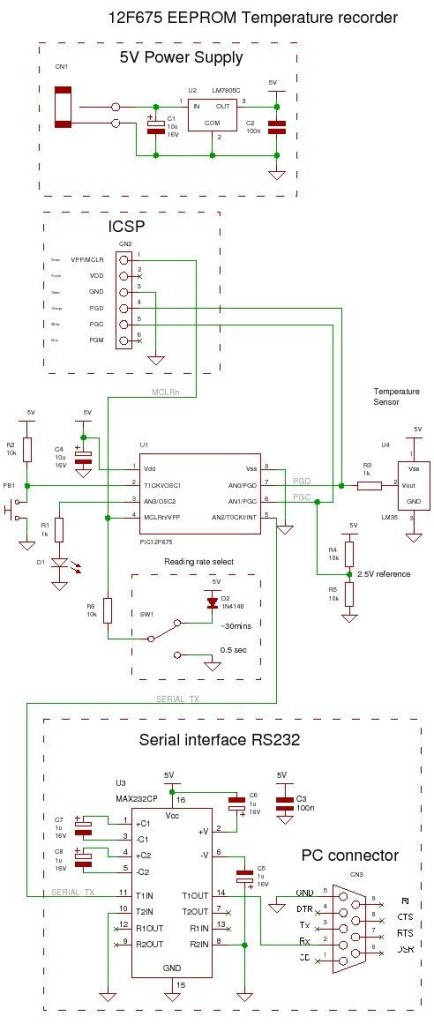

From the datasheet you will notice that the Microchip PIC12F683 microcontroller only has one PWM output (CCP1) and four ADC input channel (AN0, AN1, AN2 and AN3). Because we need two PWM output, therefore instead of using the PIC12F683 microcontroller build in PWM peripheral, in this tutorial I will show you how to generate the PWM signal base on the PIC12F683 microcontroller TIMER0 peripheral. The following is the complete electronic schematic for the laser projector project.

Ok before we go further with the detail; let’s list down the supporting peripherals needed to complete this laser projector project:

- Hot glue gun

- Keychain laser pointer or any available laser pointer

- 3xAA, 4.5 volt battery holder for powering the laser pointer, please use the same voltage rate used by your laser pointer.

- Two DC motor taken from the discarded PS2 Dual shock joystick

- Two toy’s car tire taken from tamiya racing car

- CD/DVD for the mirror, use a kitchen scissor to cut the CD/DVD into the two circle shape mirror with approximately 38 mm in diameter

- Some toys plastic bricks for holding the DC motor

- Breadboard

- Hardboard or acrylic is used for the base of our laser projector

- Double Tape

The following are the electronic parts and the software development tools that I used to make this laser projector project:

- Resistor: 330 (3), 1K (5) and 10K (1)

- Trimport: 10K (2)

- Capacitor: 100nF (2) and 10nF (1)

- One 100uH Inductor

- Two 1N4148 Diodes

- Two Blue and one Red Light Emitting Diode (LED)

- Two 2N2222A transistors

- One Mini Push Button Switch

- One Microchip PIC12F683 Microcontroller

- Microchip MPLAB v8.46 IDE (Integrated Development Environment)

- Microchip Macro Assembler MPASMWIN.exe v5.35, mplink.exe v4.35

- HI-TECH C Compiler for PIC10/12/16 MCUs (Lite Mode) V9.70

- Microchip PICKit3 Programmer (Firmware Suite Version: 01.25.20)

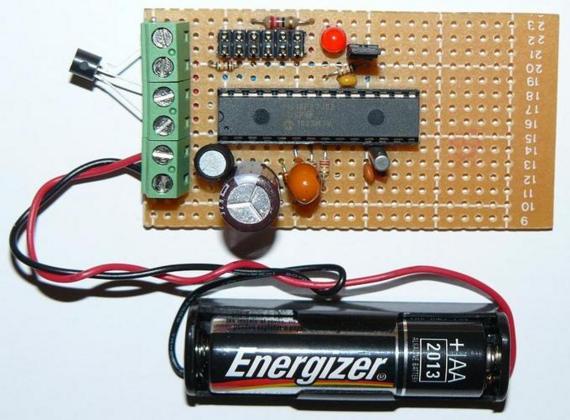

This project is aim as the continuing lessons to my previous posted blog Introduction to PIC Assembly Language Part-1 and Introduction to PIC Assembly Language Part-2, therefore I used the same PIC12F683 board presented in the part 2 which you could down load both of the electronic schematic and the PCB layout designed in Eagle CAD format. The other interesting feature of this laser projector project is; besides the PIC assembly code I also provide the C language version of this project for the C language lover and is compiled with the HI-TECH C Compiler (recently the HI-TECH Software has been acquired by Microchip). This C language version could be used for learning as well as the embedded system programming language comparison.

In this project I also use a new Microchip PICKit3 programmer but of course you could use the Microchip PICKit2 programmer to download the hex code to the PIC12F683 microcontroller flash.

![Building your own Simple Laser Projector using the Microchip PIC12F683]()

The following is the Laser Projector code in PIC Assembly Language:

;******************************************************************************

; File Name : laserlight.asm

; Version : 1.0

; Description : Laser Light Show Project

; Author : RWB

; Target : Microchip PIC12F683 Microcontroller

; Compiler : Microchip Assembler (MPASMWIN.exe v5.35, mplink.exe v4.35)

; IDE : Microchip MPLAB IDE v8.46

; Programmer : PICKit3 (Firmware Suite Version: 01.25.20)

; Last Updated : 01 April 2010

; *****************************************************************************

#include <p12F683.inc>

__config (_INTRC_OSC_NOCLKOUT & _WDT_OFF & _PWRTE_OFF & _MCLRE_OFF & _CP_OFF & _IESO_OFF & _FCMEN_OFF)

#define MAX_TMR0 0xFB

#define MAX_COUNT .200

#define MAX_DEBOUNCE 0x0A

#define MAX_TBLINDEX 0x0A

; Define variables used

cblock 0x20

Delay:2 ; Define two registers for the Delay and Delay + 1

mode ; Operation Mode

pwm_count ; Hold the Main PWM Counter

pwm_m1 ; Hold the PWM width for Motor 1

pwm_m2 ; Hold the PWM width for Motor 2

keycount ; Debounce Count

tableindex ; Table Index for Auto PWM

endc

; Define variable use for storing STATUS and WREG register

cblock 0x70 ; Use unbanked RAM, available both in Bank0 and Bank1

saved_w

saved_status

endc

; Start the Light show Assembler Code here

org 0x00 ; We always start at flash address 0

goto Main ; Jump to Main

org 0x04 ; 0x04: Start PIC Interrupt Address

PIC_ISR: ; Start the PIC Interrupt Service Routine

movwf saved_w ; Save Working Register

movf STATUS,w ; Save Status Register

movwf saved_status

; Check the TIMER0 Interrupt here

btfss INTCON,T0IF

goto ExitISR ; If (T0IF != 1) then Exit ISR

bcf STATUS,RP0 ; Select Registers at Bank 0

incf pwm_count ; pwm_count++

movlw MAX_COUNT

subwf pwm_count,w ; if (pwm_count < MAX_COUNT) then CheckPWM

btfss STATUS,C ; else clear GP1 and GP2

goto CheckPWM

bcf GPIO,GP1 ; GPIO1=0

bcf GPIO,GP2 ; GPIO2=0

goto ExitPWM

CheckPWM:

movf pwm_m1,w

subwf pwm_count,w

btfsc STATUS,Z ; if (pwm_count == pwm_m1) then Set GP1

bsf GPIO,GP1 ; Set GP1 Bit

CheckM2:

movf pwm_m2,w

subwf pwm_count,w

btfsc STATUS,Z ; if (pwm_count == pwm_m2) then Set GP2

bsf GPIO,GP2 ; Set GP2 bit

ExitPWM:

bcf INTCON,T0IF ; clear the TIMER0 interrupt flag

movlw MAX_TMR0

movwf TMR0 ; TMR0 = MAX_TMR0

ExitISR:

movf saved_status,w

movwf STATUS ; Restore STATUS Register

swapf saved_w,f

swapf saved_w,w ; Restore W Register

retfie ; Return from Interrupt

Main:

bsf STATUS,RP0 ; Select Registers at Bank 1

movlw 0x70

movwf OSCCON ; Set the internal clock speed to 8 MHz

movlw 0x39 ; GP1 and GP2 Output, GP0,GP3,GP4 and GP5 as Input

movwf TRISIO ; TRISIO = 0x39

bcf STATUS,RP0 ; Select Registers at Bank 0

movlw 0x07

movwf CMCON0 ; Turn off Comparator (GP0, GP1, GP2)

clrf GPIO

; Now we Set the ADC Peripheral

bsf STATUS,RP0 ; Select Registers at Bank 1

movlw 0x79 ; Set AN0 (GP0) and AN3 (GP4) as Analog Input

movwf ANSEL ; Using the Internal Clock (FRC)

; Now we set the TIMER0 Peripheral

; TIMER0 Period = 1/FSOC x 4 x Prescale x TMR0

movlw 0x00 ; Use TIMER0 Prescaler 1:2, Internal Clock

movwf OPTION_REG ; OPTION_REG = 0x00

bcf STATUS,RP0 ; Select Registers at Bank 0

movlw MAX_TMR0

movwf TMR0 ; TMR0=MAX_TMR0

; Initial the variables used

clrf mode ; Default mode = 0, Light Show Off

clrf pwm_count ; pwm_count = 0

clrf pwm_m1 ; pwm_m1 = 0

clrf pwm_m2 ; pwm_m2 = 0

clrf keycount ; keycount = 0

clrf tableindex ; tableindex = 0

; Activate the Interrupt

bsf INTCON,GIE ; Enable Global Interrupt

MainLoop:

btfsc GPIO,GP5 ; Now we check the Button

goto CheckMode ; if (GP5 != 0) goto CheckMode

movlw 0x01

addwf keycount ; keycount=keycount + 1

movf keycount,w

sublw MAX_DEBOUNCE

btfss STATUS,C ; if (keycount > MAX_DEBOUNCE) goto KeyPressed

goto KeyPressed

goto CheckMode ; else CheckMode

KeyPressed:

clrf keycount ; keycount=0

incf mode ; mode++

movlw 0x03

subwf mode,w ; W = mode - 0x03

btfsc STATUS,C ; if (mode >= 0x03)

clrf mode ; mode=0;

movlw 0x01 ; else check the mode

subwf mode,w

btfss STATUS,C ; if (mode >= 0x01) goto TurnOn

goto TurnOff ; else goto TurnOff

goto TurnOn

TurnOff:

bcf INTCON,T0IE ; Disable TIMER0 Interrupt

clrf pwm_count ; pwm_count = 0

clrf pwm_m1 ; pwm_m1 = 0

clrf pwm_m2 ; pwm_m2 = 0

bcf GPIO,GP1

bcf GPIO,GP2

movlw .250

call DelayMs ; DelayMs(250)

movlw .250

call DelayMs ; DelayMs(250)

goto CheckMode

TurnOn:

bsf INTCON,T0IE ; Enable TIMER0 Interrupt

CheckMode:

movlw 0x01

subwf mode,w

btfss STATUS,Z ; if (mode == 1) goto ShowMode1

goto CheckMode2

goto ShowMode1

CheckMode2:

movlw 0x02

subwf mode,w

btfss STATUS,Z ; if (mode == 2) goto ShowMode2

goto KeepLoop

goto ShowMode2

ShowMode1: ; Used ADC for PWM

movlw B'00000001' ; Left Justify and turn on the ADC peripheral, channel 0 (AN0)

movwf ADCON0 ; Vreff=Vdd

bsf ADCON0,GO ; Start the ADC Conversion on channel 0 (AN0)

btfss ADCON0,GO ; while(GO == 1)

goto $-1 ; Keep Loop

call Delay1ms

movlw B'00000001' ; Left Justify and turn on the ADC peripheral, channel 0 (AN0)

movwf ADCON0 ; Vreff=Vdd

bsf ADCON0,GO ; Start the ADC Conversion on channel 0 (AN0)

btfss ADCON0,GO ; while(GO == 1)

goto $-1 ; Keep Loop

movf ADRESH,w ; Conversion Done, Read ADRESH

movwf pwm_m1 ; pwm_m1 = ADRESH

call Delay1ms

movlw B'00001101' ; Left Justify and turn on the ADC peripheral, channel 3 (AN3)

movwf ADCON0 ; Vreff=Vdd

bsf ADCON0,GO ; Start the ADC Conversion on channel 3 (AN3)

btfss ADCON0,GO ; while(GO == 1)

goto $-1 ; Keep Test

call Delay1ms

movlw B'00001101' ; Left Justify and turn on the ADC peripheral, channel 3 (AN3)

movwf ADCON0 ; Vreff=Vdd

bsf ADCON0,GO ; Start the ADC Conversion on channel 3 (AN3)

btfss ADCON0,GO ; while(GO == 1)

goto $-1 ; Keep Test

movf ADRESH,w ; Conversion Done, Read ADRESH

movwf pwm_m2 ; pwm_m2 = ADRESH

call Delay1ms

goto KeepLoop

ShowMode2: ; Used Predefined Value for PWM

movf tableindex,w

call tablepwm1 ; Call tablepwm1

movwf pwm_m1 ; Assigned it to pwm_m1

movlw .30

call DelayMs ; DelayMs(30)

movf tableindex,w

call tablepwm2 ; Call tablepwm2

movwf pwm_m2 ; Assigned it to pwm_m2

movlw .30

call DelayMs ; DelayMs(30)

incf tableindex ; tableindex++

movlw MAX_TBLINDEX

subwf tableindex,w

btfss STATUS,C ; if (tableindex >= 0x0A) then tableindex = 0

goto KeepLoop

clrf tableindex ; tableindex = 0

KeepLoop:

goto MainLoop ; Goto MainLoop

; Predefined value table for Automatic PWM

tablepwm1:

addwf PCL,f

retlw 0x10

retlw 0x5A

retlw 0x9A

retlw 0x20

retlw 0x40

retlw 0x8A

retlw 0x82

retlw 0x30

retlw 0x58

retlw 0xAA

tablepwm2:

addwf PCL,f

retlw 0x70

retlw 0x8A

retlw 0x2A

retlw 0x30

retlw 0x1C

retlw 0x2A

retlw 0x4B

retlw 0xA0

retlw 0x18

retlw 0x2A

;----------------- DelayMs: Millisecond Delay Subroutine ----------------------

; Paramater: WREG = delay amount in milisecond, max: 255 millisecond

DelayMs:

movwf Delay + 1

DelayLoop:

call Delay1ms

decfsz Delay + 1,f ; Decrease Delay + 1, If zero skip the next instruction

goto DelayLoop ; Not zero goto DelayLoop

return ; return to the caller

;----------------- Delay1ms: 1 ms Delay Subroutine ---------------------------

Delay1ms: ; Total Delay: 1998 x 0.5us ~ 1 ms

movlw 0x99

movwf Delay

DelayLoop1:

decfsz Delay,f ; Decrease Delay, If zero skip the next instruction

goto DelayLoop1

DelayLoop2:

decfsz Delay,f ; Decrease Delay, If zero skip the next instruction

goto DelayLoop2 ; Not zero goto DelayLoop2

DelayLoop3:

decfsz Delay,f ; Decrease Delay, If zero skip the next instruction

goto DelayLoop3 ; Not zero goto DelayLoop2

return ; Return to the caller

end

; EOF: laserlight.asm

The following is the Laser Projector Project code in C Language version:

// ***************************************************************************

// File Name : laserlight.c

// Version : 1.0

// Description : Laser Light Show Project

// Author : RWB

// Target : Microchip PIC12F683 Microcontroller

// Compiler : HI-TECH C PIC10/12/16 MCUs (Lite Mode) V9.70

// IDE : Microchip MPLAB IDE v8.46

// Programmer : PICKit3 (Firmware Suite Version: 01.25.20)

// Last Updated : 03 April 2010

// ***************************************************************************

#include <pic.h>

/* PIC Configuration Bit:

** INTIO - Using Internal RC No Clock

** WDTDIS - Wacthdog Timer Disable

** PWRTEN - Power Up Timer Enable

** MCLRDIS - Master Clear Disable

** UNPROTECT - Code Un-Protect

** UNPROTECT - Data EEPROM Read Un-Protect

** BORDIS - Borwn Out Detect Disable

** IESODIS - Internal External Switch Over Mode Disable

** FCMDIS - Monitor Clock Fail Safe Disable

*/

__CONFIG(INTIO & WDTDIS & PWRTEN & MCLRDIS & UNPROTECT \

& UNPROTECT & BORDIS & IESODIS & FCMDIS);

// Using Internal Clock of 8 MHz

#define FOSC 8000000L

#define MAX_COUNT 200

#define MAX_TMR0 0xFB

#define MAX_DEBOUNCE 0x0A

#define MAX_TBLINDEX 0x0A

unsigned char pwm_count=0;

unsigned char pwm_m1=0;

unsigned char pwm_m2=0;

unsigned char tablepwm1[10]={0x10,0x5A,0x9A,0x20,0x40,0x8A,0x82,0x30,0x58,0xAA};

unsigned char tablepwm2[10]={0x70,0x8A,0x2A,0x30,0x1C,0x2A,0x4B,0xA0,0x18,0x2A};

unsigned char tableindex=0;

/* The Delay Function */

#define delay_us(x) { unsigned char us; \

us = (x)/(12000000/FOSC)|1; \

while(--us != 0) continue; }

void delay_ms(unsigned int ms)

{

unsigned char i;

do {

i = 4;

do {

delay_us(164);

} while(--i);

} while(--ms);

}

static void interrupt isr(void)

{

if(T0IF) { // TIMER0 Interrupt Flag

pwm_count++; // PWM Count Increment

if (pwm_count >= MAX_COUNT) {

pwm_count=0;

GPIO1=0; // Turn off GP1

GPIO2=0; // Turn off GP2

}

if (pwm_count == pwm_m1) {

GPIO1=1; // Turn On GP1

}

if (pwm_count == pwm_m2) {

GPIO2=1; // Turn On GP2

}

TMR0 = MAX_TMR0; // Initial Value for TIMER0 Interrupt

T0IF = 0; // Clear TIMER0 interrupt flag

}

}

void main(void)

{

unsigned char mode,keycount;

OSCCON=0x70; // Select 8 MHz internal clock

/* Initial Port Used */

TRISIO = 0x39; // GP1 and GP2 Output, GP0,GP3,GP4 and GP5 as Input

CMCON0 = 0x07; // Turn off Comparator (GP0, GP1, GP2)

GPIO = 0x00; // Turn Off all IO

/* Init ADC Peripheral */

ANSEL = 0x79; // Set AN0 (GP0) and AN3 (GP4) as Analog Input, Internal Clock

/* Init TIMER0: TIMER0 Period = 1/FSOC x 4 x Prescale x TMR0*/

OPTION = 0b00000000; // 1:2 Prescale

TMR0=MAX_TMR0 ;

/* Init Variable Used */

pwm_count=0;

pwm_m1=0;

pwm_m2=0;

mode=0;

keycount=0;

tableindex=0;

GIE =1; // Enable Global Interrupt

for(;;) {

// Display the LED

if (GPIO5 == 0) {

keycount++;

if (keycount > MAX_DEBOUNCE) {

keycount=0;

mode = mode + 1;

if (mode > 2) mode = 0;

if (mode >= 0x01) {

T0IE = 1; // Enable TIMER0 Interrupt on Overflow

} else {

T0IE = 0; // Disable TIMER0 Intterupt on Overflow

pwm_count=0;

pwm_m1=0;

pwm_m2=0;

GPIO1=0; // Turn off GP1

GPIO2=0; // Turn off GP2

delay_ms(500);

}

}

}

if (mode == 1) {

/* Read the ADC here */

ADCON0=0b00000001; // select left justify result. ADC port channel AN0

GODONE=1; // initiate conversion on the channel 0

while(GODONE) continue; // Wait for ldr_left conversion done

pwm_m1=ADRESH; // Read 8 bits MSB, Ignore 2 bits LSB in ADRESL

delay_ms(1);

/* Read the ADC here */

ADCON0=0b00001101; // select left justify result. ADC port channel AN3

GODONE=1; // initiate conversion on the channel 4

while(GODONE) continue; // Wait for ldr_left conversion done

pwm_m2=ADRESH; // Read 8 bits MSB, Ignore 2 bits LSB in ADRESL

delay_ms(1);

}

if (mode == 2) {

pwm_m1=tablepwm1[tableindex];

delay_ms(10);

pwm_m2=tablepwm2[tableindex];

delay_ms(10);

tableindex++;

if (tableindex >= MAX_TBLINDEX)

tableindex = 0;

}

}

}

/* EOF: laserlight.c */

Generating the PWM (Pulse Width Modulation)

For more detail: Building your own Simple Laser Projector using the Microchip PIC12F683 Microcontroller

The post Building your own Simple Laser Projector using the Microchip PIC12F683 Microcontroller appeared first on PIC Microcontroller.